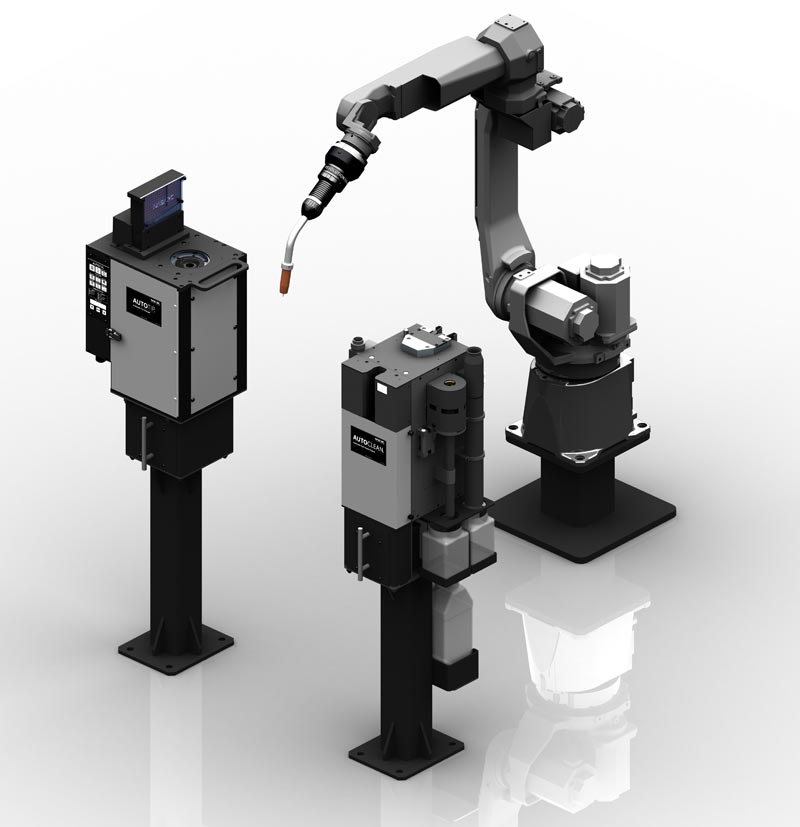

autoclean®

robotic torch maintenance center

Designed to improve overall equipment effectiveness in robotic MIG welding cells, the fully automated AUTOCLEAN® from Nasarc is engineered to increase productivity and quality while minimizing downtime and costs.

Features

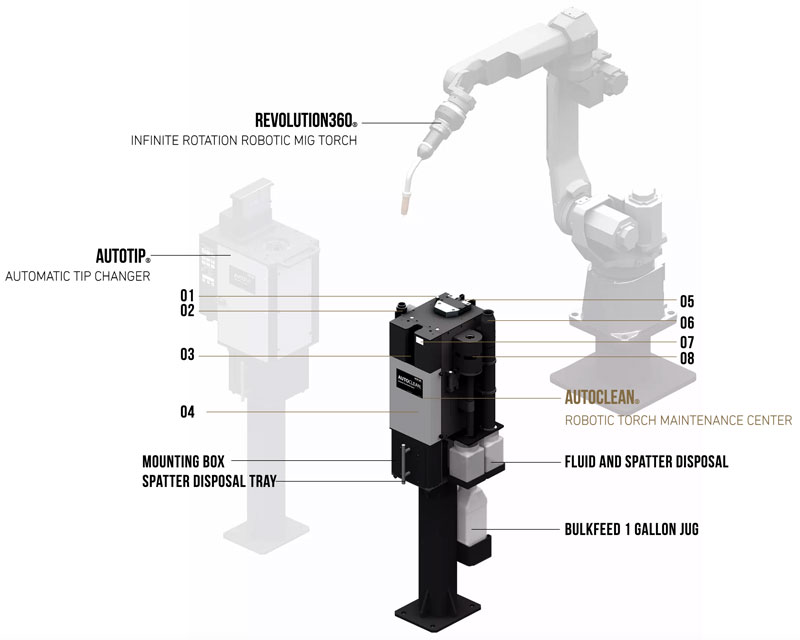

01

Automated Nozzle Reamer

Independent reaming cycle using a high strength coated reaming bit designed to effectively remove and discard spatter from nozzle.

02

Automated Nozzle Removal and Replacement

Fully automated removal and replacement allows access to contact tip and diffuser for enhanced cleaning, an industry first.

Engineered to support rapid tip change-out when used in combination with the AUTOTIP® automatic tip changer.

03

Automated Tip and Diffuser Cleaning

Rotary wire brush design ensures thorough cleaning of diffuser portholes and contact tip for more reliable gas delivery and reduced porosity.

04

Automated Wire Cutter

Innovative pinch-off wire cutter design creates a “V” shape for optimal arc starts.

Powerful and precise enough to handle all wire sizes up to 0.063” mild steel.

05

Automated Anti-Spatter Sprayer

Vortex action sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle and help prevent spatter buildup.

06

Nozzle Gas Flow Sensor

Designed to detect and measure adequate gas flow at the point of use.

07

Nozzle Presence Sensor

Post- cleaning, presence sensor ensures the nozzle is secured and ready for the next weld.

08

Intuitive User Interface

Designed to allow for easy setup, diagnostics and reporting at point of use.

TECHNICAL DATA

Footprint Size: 18” H x 11.5” L x 10” W

Air Supply: 85 PSI, 22 CFM

Power Supply: 24 VDC, 1.0 A

Benefits

Cycle Time

Process features minimize overall robot cycle time.

Quality

Enhanced torch cleaning improves gas flow and minimizes weld defects.

Flexibility

Eight processes in a small envelope offers maximum flexibility.

Safety

Operator entry into robot weld cell is reduced.

Powerful

High torque, high power industry benchmark ream motor.

Eight Processes

01 TCP check pin verifies positional accuracy of the tool center point.

02 Nozzle gas flow sensor detects gas flow at the point of use.

03 Nozzle removal and replacement enables tip and diffuser cleaning.

04 Automated reaming cycle uses a high strength coated reaming bit.

05 Pinch-off wire cutter creates a "V" tip for optimal arc starts.

06 Anti-spatter sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle.

07 Nozzle presence sensor verifies the nozzle is secured and ready for the next weld.

08 Tip and diffuser cleaner with rotary brush offers enhanced torch maintenance.

User Interface

Easy access to information at point of use

• Intuitive user interface available for setup and robot programming.

• On-board controls are used to measure and manage internal functions and communications with the robot.

• LCD readout allows for complete setup and diagnostics.

Web server-extended user interface

• Built-in web server user interface offers enhanced diagnostics, configuration, remote monitoring and analytics.

Robot Integration

robot integration Robot integration implemented through Ethernet/IP.

Ethernet/ip:

• Expanded I/O for enhanced control

• Cycle counters on each process

• Consumable management

• Error codes

• Process diagnostics

• RS-logix AOI is available for easy integration

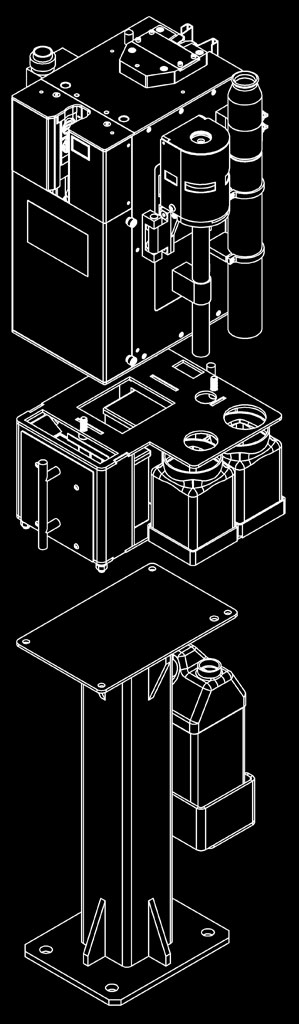

Flexible Mounting Options

The mounting box may be installed on the recommended stand (sold separately) with various heights available, on a custom stand, or on a fixture.

Ordering Information

1. autoclean®

| Ethernet/IP | NAC1E |

2. Nozzle Clamp (required)

| Standard Duty Nozzle Clamp | NAC08-1R |

| Heavy Duty Nozzle Clamp | NAC08-2R |

3. Reaming Bit (required)

| Ream Bit for 5/8" Nozzle | IRB020625-00 |

| Ream Bit for 1/2" Nozzle | IRB020501-00 |

4. Anti Spatter Bulk Feed (recommended)

| NAC34 | |

5. Cable (recommended)

| Ethernet/IP 4 pin power cable 30 ft | NCCA-F-30 |

| Ethernet/IP M12/RJ45 cable 30 ft | NCCD-R-30 |

6. Mounting (recommended)

| Mounting Box & Tray Assembly (NAC) | NSMC1-07 |

| Stand Post Assembly 23" | NSSC1-23 |

7. Replacement Parts

| Diffuser Brush Set | NAC20-3R |

| Wire Cutter Module | NAC10-2R |