Click on the boxes below to view additional options available for this product. (Multiple options may be chosen).

*Mounting box (see options below)

*Mounting stand (see options below)

INTELLIREAM® DD - EIP COBOT

direct drive robotic torch maintenance center

For Collaborative Robots

Ethernet Industrial Protocol

Extend the life of your cobot MIG torch and improve cycle time in your cobot welding cell with the Nasarc Intelliream® DD-EIP-COBOT (Ethernet Industrial Protocol) model. Designed to improve overall welding equipment effectiveness, this torch maintenance center systematically removes and limits spatter accumulation for enhanced productivity.

The Intelliream® DD-EIP-COBOT model provides additional functionality including: enhanced command and diagnostic signals, direct access to process controls and feature configuration. The complete process is managed by the internal CPU.

Product Advantages

Automated Nozzle Reamer:

Independent reaming cycle uses a high-strength coated reaming bit designed to effectively remove and discard spatter from the nozzle. A two stage de-ringer removes the spatter ring at the bottom of the nozzle before reaming. The automatic retry feature ensures the nozzle is reamed to full depth.

Automated Wire Cutter:

The innovative pinch-off wire cutter design creates a “V” shape for optimal arc starts. It is powerful and precise enough to handle all wire sizes up to 1/16” mild steel.

Automated Anti-Spatter Sprayer:

Vortex action sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle and help prevent spatter buildup. The anti-spatter fluid reservoir may be mounted remotely.

Nozzle Gas Flow Sensor:

Designed to detect and measure adequate gas flow at the point of use.

Nozzle Presence Sensor:

Post-cleaning, presence sensor ensures the nozzle is secured and ready for the next weld.

Intuitive User Interface:

Designed to allow for easy setup, diagnostics and reporting at point of use.

Safety:

Additional guarding for collaborative robot (cobot) welding.

TECHNICAL DATA

Footprint Size: 19” H x 12” L x 10” W

Cutter Speed: 320 RPM

Air Driven Motor: 0.50 HP

Wire Cutter Diameter: 0.030” - 0.0625”

Air Supply: 80 PSI, 17 SCFM

Power Supply: 24 VDC, 0.75 A

process highlights

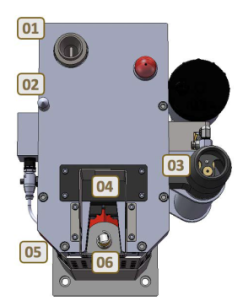

01 Nozzle gas flow sensor detects gas flow at the point of use.

02 TCP check pin verifies positional accuracy of the tool center point.

03 Vortex action sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle.

04 Pinch-off wire cutter is integrated in the clamp housing for easy and quick access, minimizing cobot movement.

05 Nozzle detect ensures that the nozzle is fastened on the torch.

06 Automated reaming cycle uses a high-strength coated reaming bit.

performance

The networked Intelliream® DD-EIP-COBOT provides additional performance over traditional reamers.

• Ease of installation and seamless integration with controller.

• Troubleshooting via diagnostics at the cobot or PLC.

• Expandable platform for feature upgrades.

• Single connection for multiple cobots.

• Data acquisition of process counters and solenoid/cylinder activation timers.

features & benefits

The Intelliream® DD-EIP-COBOT torch maintenance center incorporates the following advantages enabled by network connectivity:

01 Separate connections for control and solenoid power. The solenoid power may be tied into a safety circuit and interrupted in an emergency condition. The control connection supplies power to the node and sensors in order to maintain network communications.

02 Advanced diagnostic and troubleshooting tools helps pinpoint issues and decrease downtime.

03 Consumable usage and replacement alerts (anti-splatter fluid, wire cutter, ream bit) assist with preventative maintenance efforts.

04 Add-on instruction (AOI) is available for Logix PLCs to cut integration time and costs.

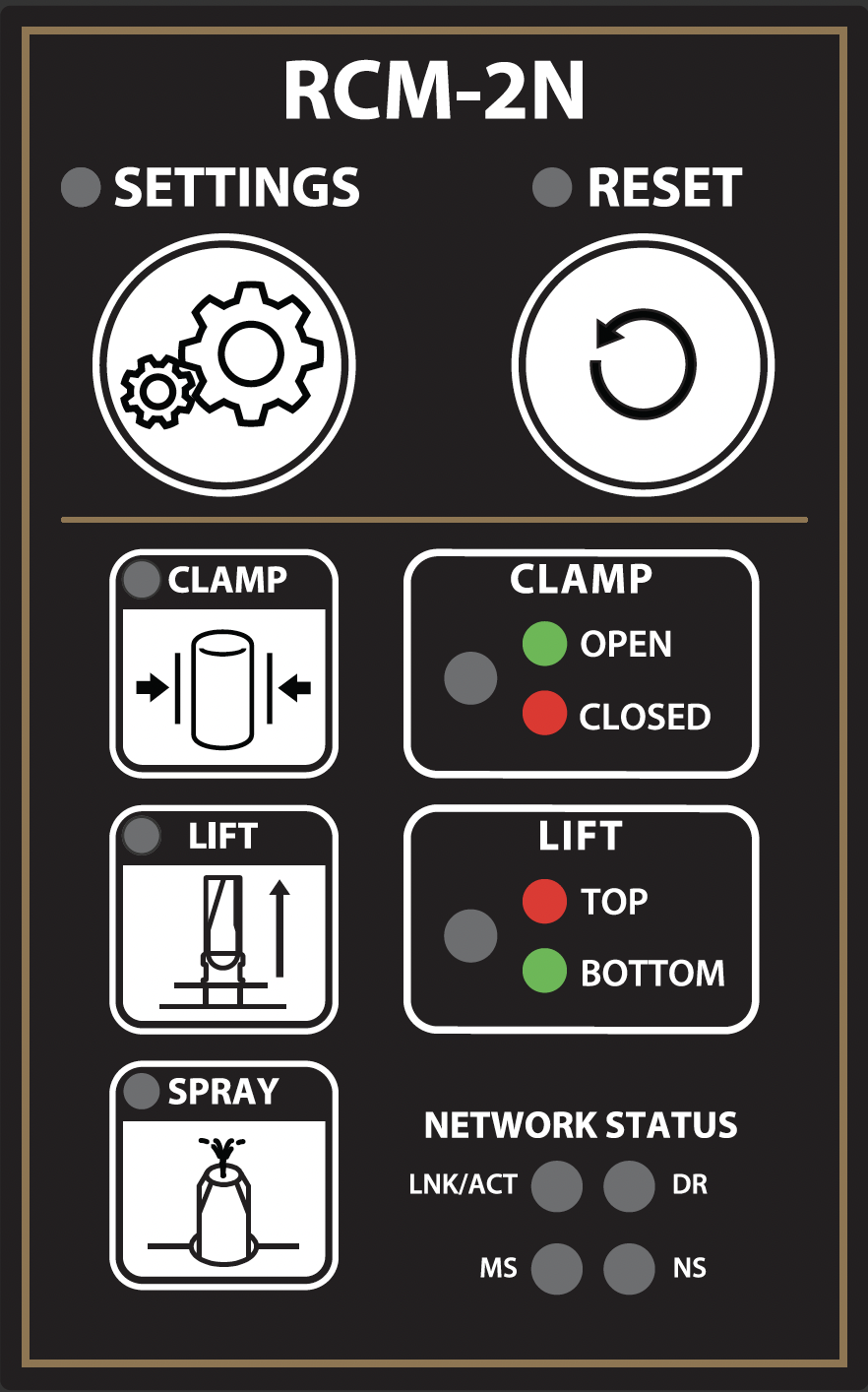

• The electronics are enclosed in the RCM-2N control module. The control module is easily removed from the side of the machine and disconnected without removing the front or rear panels.

• Magnetic sensors are utilized for optimum position accuracy and reliability.

• Dry-run and sensor override modes make setting up and trouble-shooting easier.

• Self-centering grip design for positive traction on all nozzle sizes.

• On-board diagnostics indicate position and fault codes for ease of troubleshooting.

• A status light signals when the unit is operating and flashes diagnostic codes if a fault occurs.

flexible mounting options

There are 2 mounting options.

1) Mounting box - A mounting box can be used to mount on any fixture or table.

2) Floor Mount stand (various heights available)

Ordering Information

Standard Equipment

| INTELLIREAM® DD-EIP-COBOT | IRM040002-DD-EIP |

| Spray System | |

| TCP Check | |

| Status Light | |

| De-ringer | |

| Fluid Reservoir |

factory installed options

| Mounting Box | IRX120099-00 |

| Wire Cutter | IRW010099-00 |

| Nozzle Detect Assembly | IRE120099-02 |

| Nozzle Gas Flow Sensor DD | IRE120099-04 |

Accessories

| Reaming Bit, 1/2" | IRB010500-00 |

| Reaming Bit, 1/2" bottleneck | IRB010501-00 |

| Reaming Bit, 15.5mm | IRB01M155-00 |

| Reaming Bit, 5/8" | IRB020625-00 |

| Reaming Bit, 3/4" | IRB010750-00 |

| Power Cable 4 pin, 90 degree, 30 ft | IRE120006-00 |

| Ethernet/IP M12/RJ45, 90 degree, 30 ft | IRE120008-00 |

| Floor Mount stand, 30" DD | IRX120099-30 |

| Anti Spatter Bulk Feed DD | IRS120099-06 |