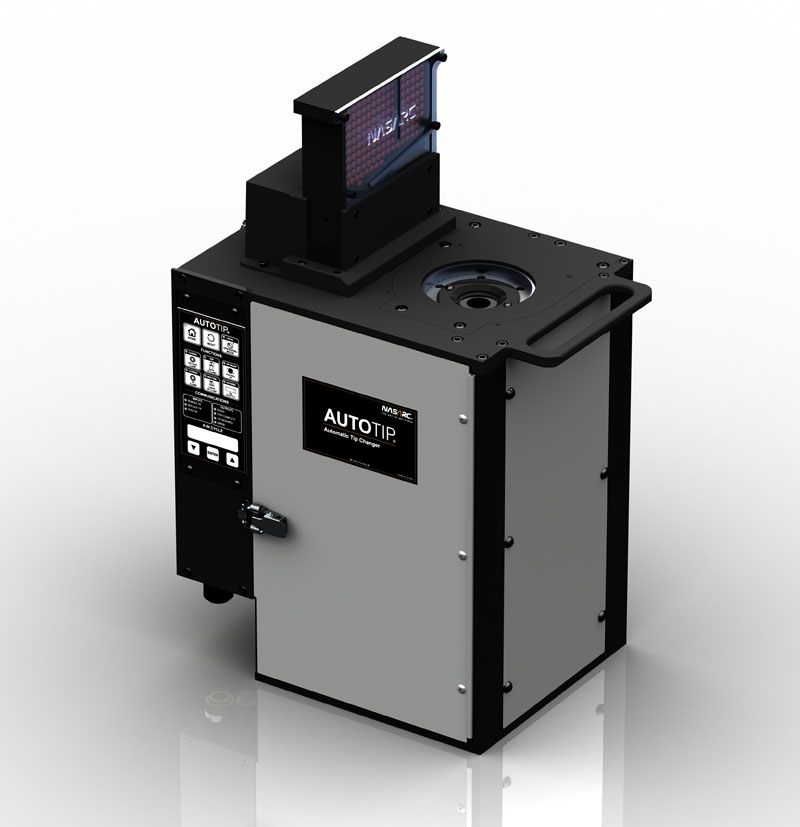

autotip®

automatic tip changer

Experience an innovation in robotic MIG welding. The AUTOTIP® from Nasarc automates the routine task of manually changing a MIG welding contact tip.

The AUTOTIP® removes and replaces a spent tip with a new tip, reducing tip changing time to as low as thirty seconds. An on-board tip cartridge allows for 175 tip changes without operator intervention.

*The AutoTip is not sold separately. It is sold as part of the Tip Exchange System.

Features

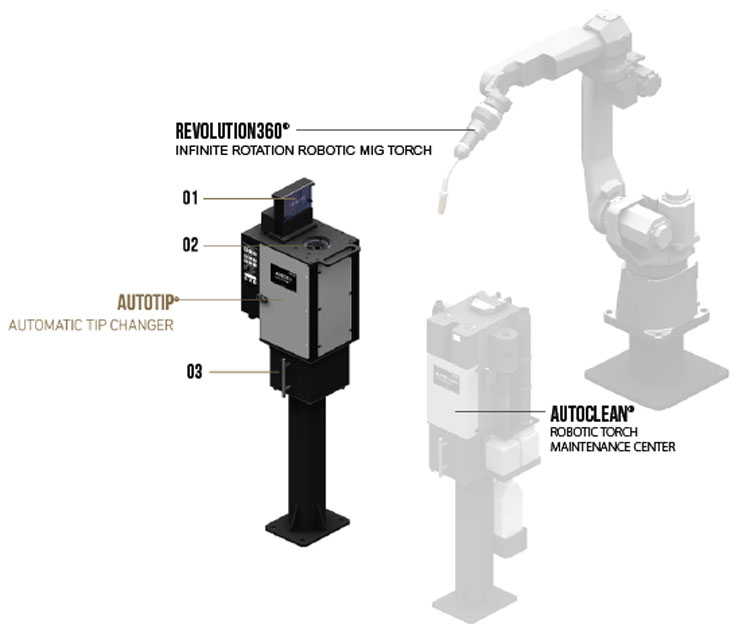

01

Automated Tip Removal and Disposal

Reduced cycle time results in increased productivity. Tip change cycle time is reduced to as low as 30 seconds when used with the AUTOCLEAN®. Used contact tips are automatically disposed of into a dedicated tray for easy cleanup.

02

Automated Contact Tip Replacement

An on-board contact tip cartridge allows for fully automated tip replacement for 175 tip changes with minimal downtime.

03

Easy Tip Cartridge Reloading

Pre-loaded cartridge allows for easy and rapid change-out.

04

Intuitive User Interface

Designed to allow for easy setup, diagnostics and reporting at point of use.

05

Industrial Network Capable

Equipped with Ethernet/IP network capability.

06

Consistent Torque Application

TECHNICAL DATA

Footprint Size: 23.1" H x 15.5" L x 10" W

Air Supply: 85 PSI, 13 CFM

Power Supply: 24 VDC, 5.0 A

Benefits

Cycle Time

Reduced downtime resulting in increased productivity. Tip change cycle time can be as low as 30 seconds when used with the AUTOCLEAN®.

Quality

Improved weld quality through consistent tip fastening torque.

Flexibility

Tip change schedule can be programmed for optimum tip performance.

Safety

Operator entry into robot weld cell is reduced.

Powerful

Capable of removing and replacing a tip with a burnback condition.

Three Processes

01 Automatic preparation of contact tip for next machine cycle.

02 Tip removal and replacement; power and precision ensure a full removal and consistent tightening torque.

03 Convenient in-stand tip disposal tray for quick and easy removal of spent tips, resulting in a cleaner welding environment.

User Interface

Easy access to information at point of use

• Intuitive user interface available for setup and robot programming.

• On-board controls are used to measure and manage internal functions and communications with the robot.

• LCD readout allows for complete setup and diagnostics.

Web server-extended user interface

• Built-in web server user interface offers enhanced diagnostics, configuration, remote monitoring and analytics.

Robot Integration

robot integration Robot integration implemented through Ethernet/IP.

Ethernet/ip:

• Intuitive user interface available for setup and robot programming.

• Expanded I/O for enhanced control

• Cycle counters on each process

• Consumable management

• Error codes

• Process diagnostics

• RS-logix AOI is available for easy integration

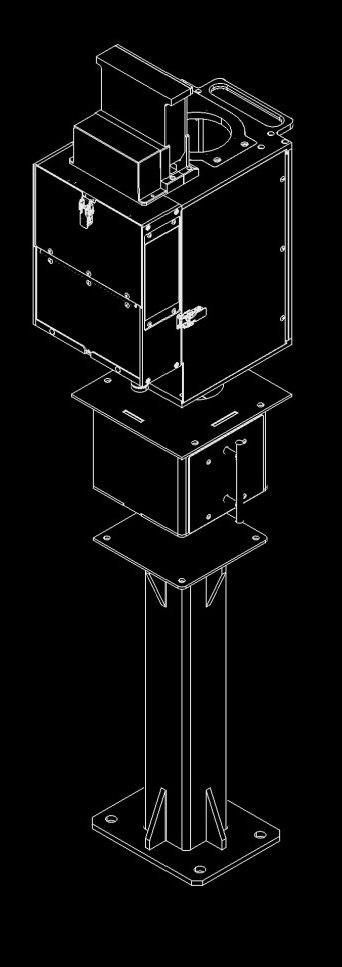

Flexible Mounting Options

The mounting box may be installed on the recommended stand (sold separately) with various heights available, on a custom stand, or on a fixture.

Ordering Information

1. autotip®

| Ethernet/IP | NAT1E |

2. contact tips (required):

| CONTACT TIP CARTRIDGE, HD COPPER DHP (QTY 175) | |

| 0.035” (0.9 mm) 0.040” (1.0 mm) 0.045” (1.2 mm) 0.052” (1.3 mm) | NTTB-35-CG175 NTTB-40-CG175 NTTB-45-CG175 NTTB-52-CG175 |

| CONTACT TIP CARTRIDGE, HD LONG LIFE CuCrZr (QTY 175) | |

| 0.035” (0.9 mm) 0.040” (1.0 mm) 0.045” (1.2 mm) 0.052” (1.3 mm) | NTTC-35-CG175 NTTC-40-CG175 NTTC-45-CG175 NTTC-52-CG175 |

4. Cable (recommended):

| Ethernet/IP 4 pin power cable 30 ft | NCCA-F-30 |

| Ethernet/IP M12/RJ45 cable 30 ft | NCCD-R-30 |

5. Mounting (recommended)

| Mounting Box & Tray Assembly (NAT) | NSMT1-07 |

| Stand Post Assembly 23" | NSST1-23 |