INTELLIFLO™ - NGFS

robotic arc welding gas flow SENSOR

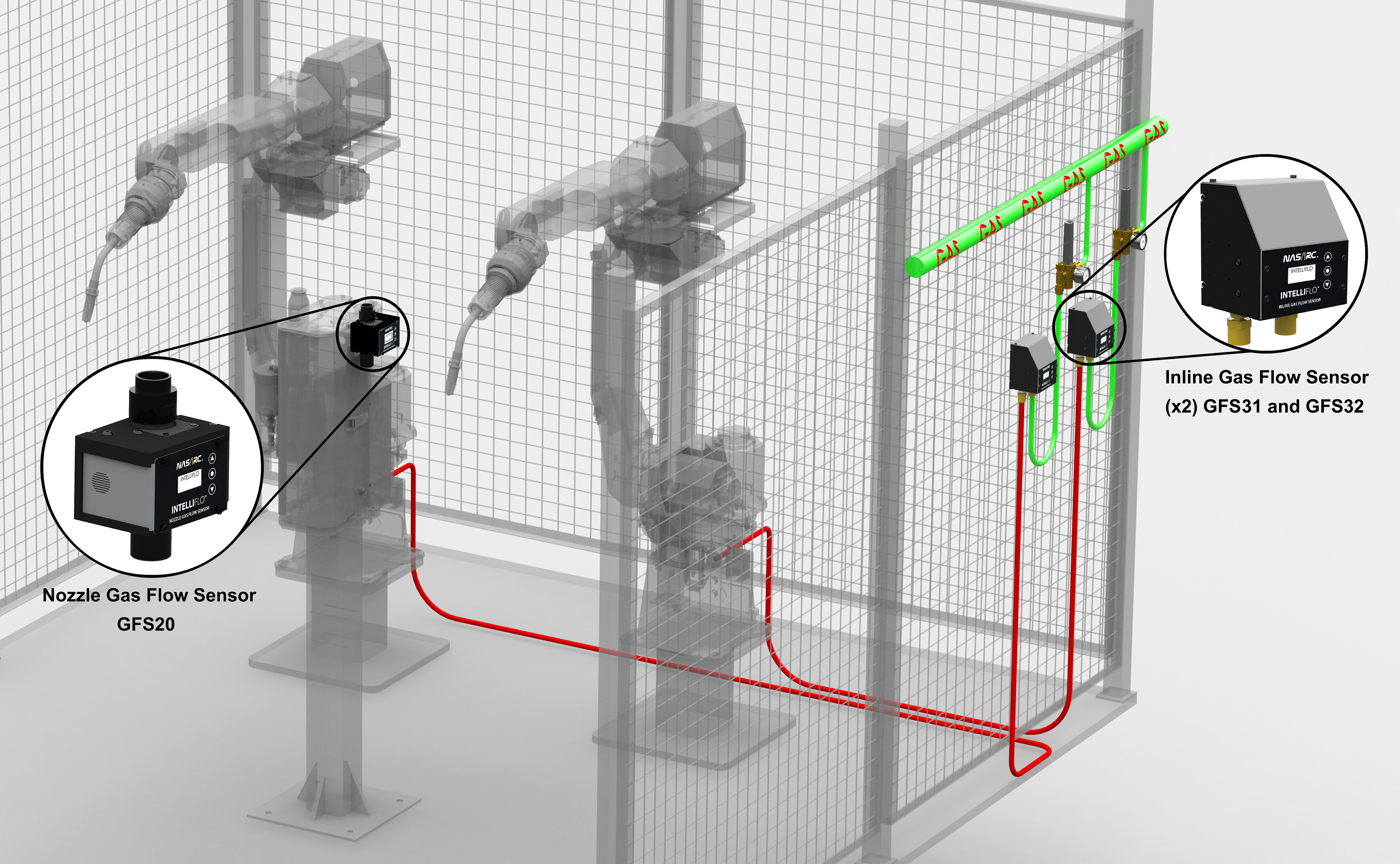

The IntelliFlo™ Nozzle Gas Flow Sensor (NGFS), an advanced welding gas flow and temperature monitoring system, is designed to elevate precision and efficiency in welding operations. This cutting-edge system provides real-time monitoring of gas flow and temperature out of the nozzle at the point of use for assurance checks between welds. By offering comprehensive insights into gas flow rates, the IntelliFlo™ NGFS promotes optimal welding conditions, resulting in higher quality welds and increased productivity. The advanced diagnostic and troubleshooting capabilities aids in satisfying the requirements of the CQI-15 audit.

Features & Benefits

Gas Flow and Temperature Monitoring:

• Measures and promotes consistent and optimal gas flow at the point of use, resulting in high-quality welds with fewer defects.

• Gas flow temperature measurement provides indirect insight into the temperature of the nozzle and contact tip, allowing for a more comprehensive understanding of consumable performance.

Real-Time Data Display with IO-Link Connectivity:

• Intuitive display interface provides realtime data on gas flow rates.

• Enables welding technicians to make immediate adjustments for optimal performance.

• IO-Link communication enables seamless connectivity for data exchange with other devices and systems, promoting interoperability.

User-Friendly Interface:

• Easy-to-navigate interface with user-friendly controls.

• Simplifies operation for both seasoned welders and those new to the technology.

Precision and Accuracy:

• High-precision sensors deliver accurate measurement of gas flow, minimizing wastage and enhancing cost-effectiveness.

• IO-Link integration provides precise and reliable communication for accurate data transmission.

• The engagement of the welding nozzle on the NGFS is spring-mounted, providing a smooth and safe contact with the flow cone, avoiding robot collision errors.

Compact and Durable Design:

• Compact form factor for easy integration into existing welding setups.

• Robust construction delivers durability in challenging welding environments.

Compatibility:

• Compatible with a wide range of welding systems and gases.

• Can be seamlessly integrated into various welding applications.

• IO-Link connectivity facilitates easy integration into industrial networks and control systems.

TECHNICAL DATA

Max Pressure 60 PSI

Power Supply 24 VDC 0.01 Amps

IO-Link ADVANTAGE

IO-Link stands as a universally embraced open standard communications protocol by sensor and controls companies worldwide. This digital, bidirectional, point-to-point interface seamlessly integrates with a wide array of automated systems. Consequently, it establishes a fully digital pathway from a weld mounted sensor to your Programmable Logic Controller (PLC).

ngfs with io-link

• Alerts operations of insufficient gas flow.

• Flow readings for various welding gas combinations.

• Outlet flow gas temperature.

• Nozzle seal confirmation sensor (positive pressure detection).

• Calibrated for AR, 90:10 and 75:25 welding gases.

• Recalibration and custom calibration is available.

BENEFITS OF IO-LINK

The IntelliFlo™ is an essential tool for welding professionals seeking to optimize their welding processes, delivering precision, efficiency, and superior weld quality with the added benefit of IO-Link communication for enhanced connectivity and data exchange.

Improved Weld Quality:

Evaluates consistent and optimal gas flow, resulting in high-quality welds with fewer defects.

Increased Productivity:

Real-time monitoring allows for quick adjustments, reducing downtime and increasing overall welding productivity.

Enhanced Diagnostic and

Troubleshooting with IO-Link:

IO-Link communication enables advanced diagnostic capabilities for prompt issue resolution.

Cost Savings:

Accurate gas flow control minimizes wastage, leading to cost savings in gas consumption.

Enhanced Safety:

Customizable alarms alert operators to potential issues, contributing to a safer working environment.

Compliance:

Helps in meeting industry standards including CQI-15 audit compliance requirements through accurate monitoring and documentation.

Nozzle Sensor Input Set points:

- Gas Selection

- Metric or Imperial Units Selection

Nozzle Sensor Output Values:

- Gas Flow

- Outlet Gas Flow Temperature

- Nozzle Seal Detection

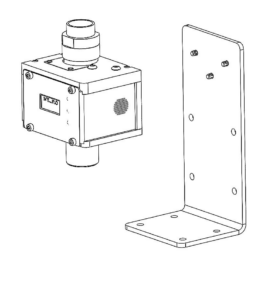

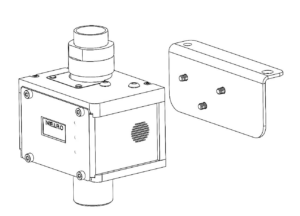

MOUNTING OPTIONS

INTELLIFLO™ NGFS

MOUNTING BRACKET GFS01-9

INTELLIFLO™ NGFS

MOUNTING KIT GFS01-10

Ordering Information

Point of Use Nozzle Gas Flow and Temperature Sensor

Intelliflo™ Nozzle Gas Flow Sensor Mounting Bracket

Intelliflo™ Nozzle Gas Flow Sensor Mounting Kit Intelliream®

IO-Link Cable, 4 pin, 10M, M12

GFS20

GFS01-9

GFS01-10

IRE060017-00