Click on the boxes below to view additional options available for this product. (Multiple options may be chosen).

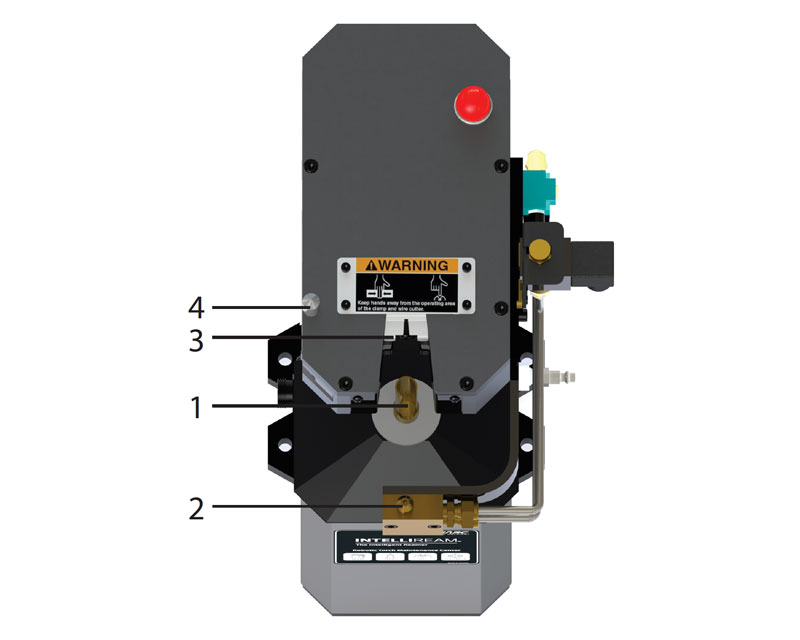

*Optional Wire Cutter is shown on all pictures

INTELLIREAM® EIP

robotic torch maintenance center

Extend the life of your robotic MIG torch and improve cycle time in your robotic welding cell with the next generation Intelliream® EIP. This robotic torch maintenance center systematically removes and limits spatter accumulation for enhanced productivity.

The ethernet enabled EIP model provides additional functionality including: enhanced command and diagnostic signals, direct access to process controls, and feature configuration, with the complete process managed by the internal CPU.

Features

01

The Intelliream® EIP controller features a simple “No Trial - No Error”

programming technique and constant process monitoring.

02

Self-centering diamond grip design for positive traction on all nozzle sizes.

03

Complete enclosure seals out small particles and contaminants.

04

On-board diagnostics indicate position and fault codes for ease of troubleshooting.

05

A status light signals when the unit is operating and flashes diagnostic codes if a fault occurs.

06

Dry run and sensor override modes make setting up and troubleshooting easier.

07

The Intelliream® is the only reamer to offer an automatic retry feature.

08

De-ringer: A pilot reaming stroke removes the spatter ring that forms on the end of the weld nozzle.

TECHNICAL DATA

Footprint Size: 25” H x 13” L x 10” W

Cutter Speed: 1100 RPM

Air Driven Motor: 0.60 HP

Wire Cutter Diameter: 0.030” - 1/16”

Air Supply: 80 PSI, 16.5 SCFM

Power Supply: 24 VDC, 0.8 A

Four Processes

01 High-strength coated reaming bit provides enhanced wear resistance. Precision machined to tight tolerances for optimized performance.

02 Vortex action sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle. Postflow logic enables self-cleaning.

03 Pinch off wire cutter is integrated in the clamp housing for easy and quick access, minimizing robot movement. (Optional)

04 Tapered cone provides a visual check to ensure positional accuracy of the TCP (tool center point).

performance

The Intelliream® EIP controls the entire reaming process. Every aspect of the reaming cycle is commanded, monitored, and verified. The feedback signal to the robot is a true "complete" signal indicating that the entire sequence has been executed without error. Modern robotic systems with network capability have advantages over their earlier discrete I/O counterparts.

The connectivity of the Intelliream® EIP provides many of these advantages including:

• Ease of installation and seamless integration with controller.

• Troubleshooting via diagnostics at the robot or PLC.

• Expandable platform for feature upgrades.

• Single connection for multiple robots.

• Data acquisition of process counters and solenoid/cylinder activation timers.

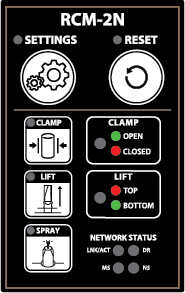

EtherNet I/P: Distributed Intelligence

- The Intelliream® EIP robotic torch maintenance center builds on the foundation of the button, actuator buttons, and indicator LEDs and the following advantages enabled by network connectivity.

- Separate connections for control and solenoid power. The solenoid power may be tied into a safety circuit and interrupted in an emergency condition. The control connection supplies power to the node and sensors in order to maintain network communications.

- More control data is available for ease of programming.

- Advanced diagnostic and troubleshooting tools helps pinpoint issues and decrease downtime.

- Consumable usage and replacement alerts (anti-spatter fluid, wire cutter, ream bit) assist with preventative maintenance efforts.

- Add-on instruction (AOI) is available for Logix PLCs to cut integration time and costs.

Web Server:

Extended user interface for enhanced functionality

Built-in web server user interface offers enhanced diagnostics, configuration, remote monitoring and analytics. Its responsive design is compatible with laptops, smart phones and tablets.

- Interface: Remote monitoring of components, and machine operating state.

- Settings: Remote operation of actuators, System configuration and troubleshooting.

- Statistics: Cycle and operations timing and counts, Error log.

- Email notification: Alarms, Consuming replacements, Performance metrics.

The following network communication protocols are available for the Intelliream® EIP: EtherNet/IP™ and Modbus TCP.

EtherNet/IP™ is a trademark of ODVA, Inc.

Ordering Information

Standard Equipment

| INTELLIREAM® EIP | IRM030001-EIP |

| Spray System | |

| TCP check |

Request any of the following options when ordering:

| Wire Cutter Module | IRW010099-00 |

| Nozzle Detect Assembly | IRE120099-02 |

| Spray Containment Assembly II | IRS020099-00 |

Accessories

| Reaming Bit, 1/2" | IRB010500-00 |

| Reaming Bit, 1/2" bottleneck | IRB010501-00 |

| Reaming Bit, 15.5mm | IRB01M155-00 |

| Reaming Bit, 5/8" | IRB020625-00 |

| Reaming Bit, 3/4" | IRB010750-00 |

| Robot control cable, 20ft | IRE010090-20 |

| Robot control cable, 30ft | IRE010090-30 |

| Robot control cable, 50ft | IRE010090-50 |

| Test Box | IRT020001-00 |

| Adapter Plate | IRF020002-01 |

| Floor Mount Stand | IRX010001-00 |

| Anti Spatter Bulk Feed | IRS010099-09 |