The INTELLIFLO™ System

Unlock the full potential of gas flow monitoring with The IntelliFlo™ system.

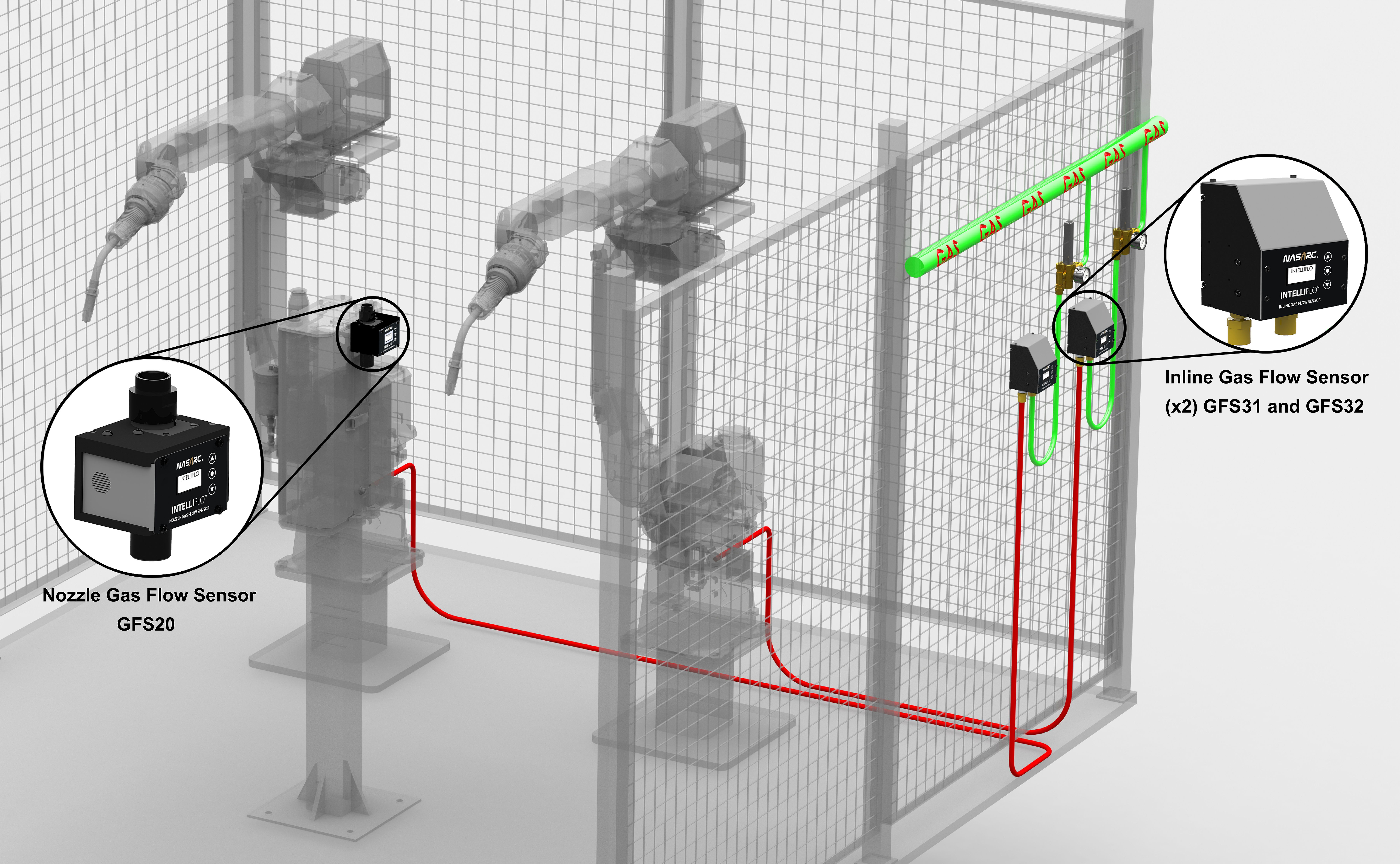

This architecture combines the Nozzle Gas Flow Sensor (NGFS) and the Inline Gas Flow Sensor (IGFS), offering a seamless turnkey solution for superior welding gas monitoring. Individually, each sensor delivers precision insights: the NGFS measures gas flow and temperature directly from the nozzle, while the IGFS monitors gas flow and pressure in the line between the regulator and wire feeder. Together, they create a highly integrated system that delivers consolidated readings, simplifies setup, and streamlines troubleshooting through a single IO-Link device. This unified approach not only eliminates the complexity of managing separate devices, but also enhances diagnostic accuracy. By leveraging calibration data stored in one memory, the system provides consistent and reliable performance across all sensors. The NGFS and IGFS together allow you to pinpoint gas flow issues more effectively, minimizing waste, improving weld quality, and maximizing productivity.

Features of using both sensors in combination

• Easily detect leaks in the system by measuring differential flow.

• Turn-key solution.

• Communication to the combined system through a single IO-Link device connection.

• Parameter settings for all sensors via IO-Link.

• Calibration for all sensors is stored in one memory.

Intelliflo™ - NGFS

nozzle gas flow sensor

Measures and promotes consistent and optimal gas flow at the point of use, resulting in high-quality welds with fewer defects.

- Nozzle Gas Flow and Temperature Monitoring

- Nozzle Seal Confirmation Sensor with Positive Pressure Feedback

- Real-Time Data Display and User Interface

- Removable Nozzle Cone

- IO-Link connectivity, Class A device

Intelliflo™ - IGFS

inline gas flow sensor

Measures and checks for consistent and optimal gas flow upstream of the gas valve, resulting in high-quality welds with fewer defects.

- Inline Gas Flow and Pressure Monitoring

- Accumulated Flow Volume

- Easy to Read Data Display in a User Friendly Interface

- Connects with NGFS in the INTELLIFLO™ system or may be use stand-alone with IO-Link

- Compact and Durable Design