INTELLIREAM® IOL

robotic torch maintenance center

Extend the life of your robotic MIG torch and improve cycle time in your robotic welding cell with the Nasarc INTELLIREAM®-IOL (IO-Link) model. Designed to improve overall welding equipment effectiveness, this robotic torch maintenance center systematically removes and limits spatter accumulation for enhanced productivity.

The INTELLIREAM®-IOL model provides additional functionality including enhanced command and diagnostic signals. The complete process is managed by the internal CPU.

Features

01

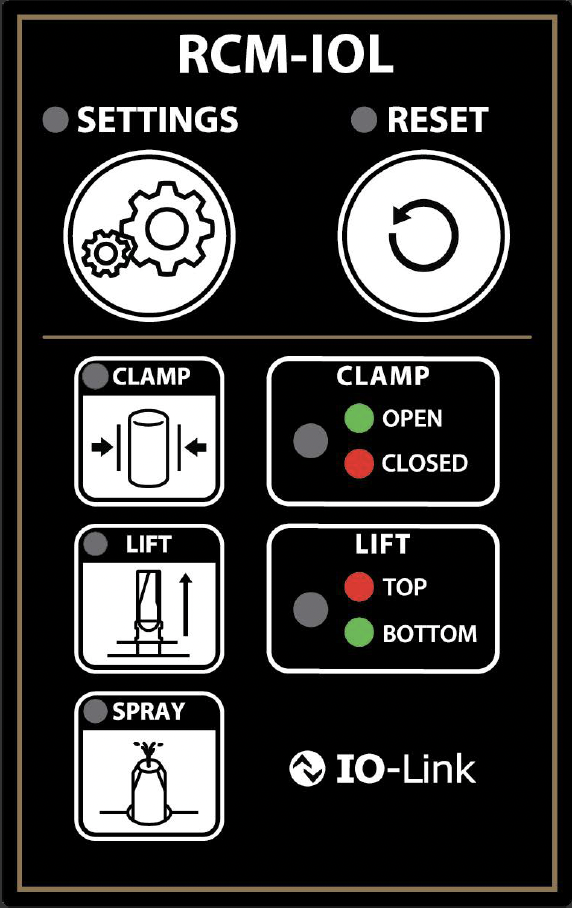

The Intelliream® MP controller features a simple “No Trial - No Error” programming technique and constant process monitoring.

02

Self-centering grip design for positive traction on all nozzle sizes.

03

Complete enclosure seals out small particles and contaminants.

04

On-board diagnostics indicate position and fault codes for ease of troubleshooting.

05

A status light signals when the unit is operating and flashes diagnostic codes if a fault occurs.

06

Dry run and sensor override modes make setting up and trouble-shooting easier.

07

The Intelliream is the only reamer to offer an automatic retry feature.

08

De-ringer: A pilot reaming stroke removes the spatter ring that forms on the end of the weld nozzle.

TECHNICAL DATA

Footprint Size: H: 20.6”, W: 11”, D: 12.1”

Cutter Speed: 1100 RPM

Air Driven Motor: 0.60 HP

Wire Cutter Diameter: 0.030" - 0.0625"

Air Supply: 80 PSI, 16.5 SCFM

Power Supply: 24 VDC, 0.75 A

Processes

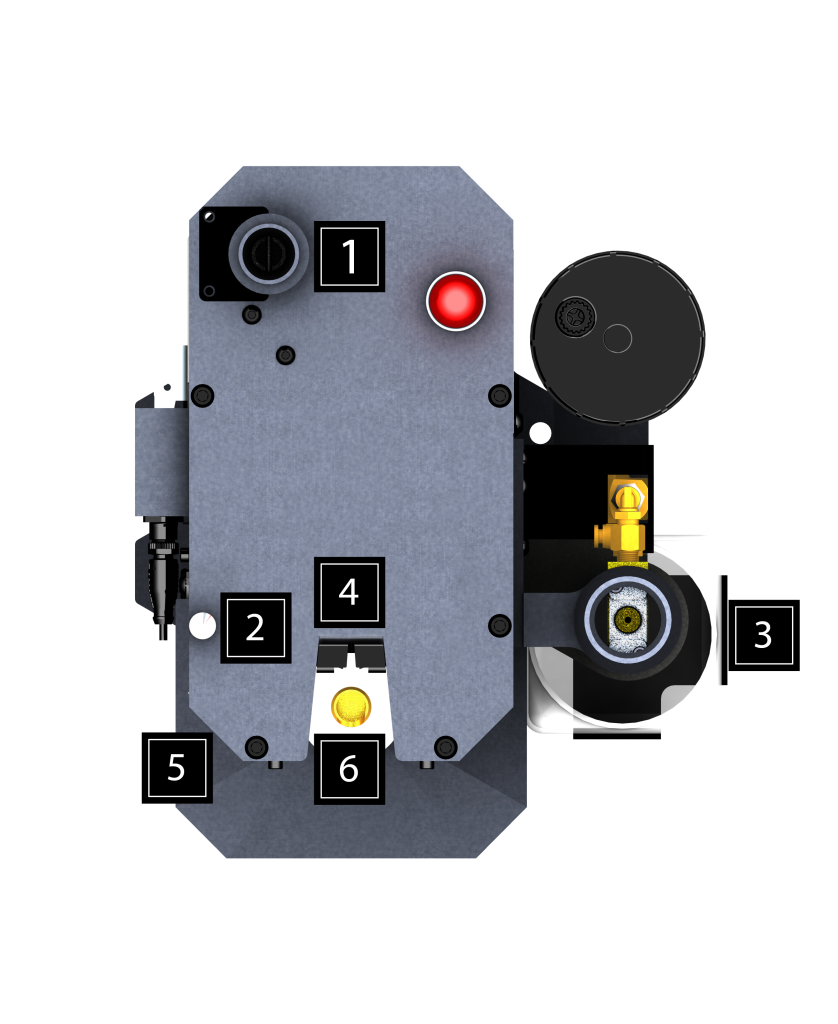

1 Nozzle gas flow sensor detects gas flow at the point of use.

2 TCP check pin verifies positional accuracy of the tool center point.

3 Vortex action sprayer delivers a radial spray pattern to uniformly coat the interior surface of the nozzle.

4 Pinch-off wire cutter is integrated in the clamp housing for easy and quick access, minimizing robot movement.

5 Nozzle detect ensures that the nozzle is fastened on the torch.

6 Automated reaming cycle uses a high-strength coated reaming bit.

Performance

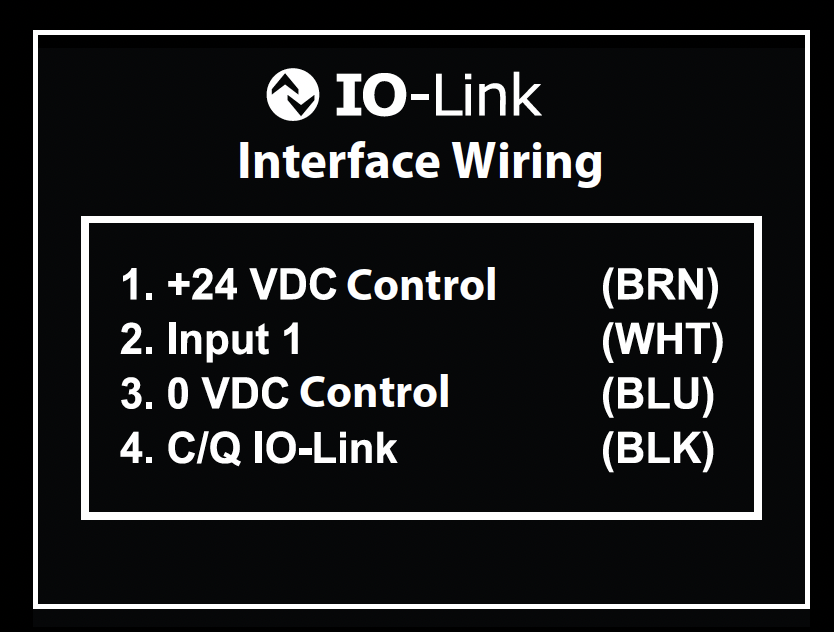

The networked INTELLIREAM®-IOL provides additional performance over traditional reamers.

• Ease of installation and seamless integration with controller.

• IO-Link is available as a port class A device.

• Troubleshooting via diagnostics at the robot or PLC.

• Expandable platform for feature upgrades.

• Single connection for multiple robots.

• Data acquisition of process counters.

industry 4.0 features & benefits

The INTELLIREAM®-IOL torch maintenance center incorporates the following advantages enabled by network connectivity:

• Advanced diagnostic and troubleshooting tools help pinpoint issues and decrease downtime.

• Cycle counter and preventive maintenance countdown will boost uptime and improve overall equipment effectiveness.

• Add-on instruction (AOI) is available for Logix PLCs to cut integration time and costs.

• Magnetic sensors are utilized for optimum position accuracy and reliability.

• Dry-run and sensor override modes make setting up and trouble-shooting easier.

• Self-centering grip design for positive traction on all nozzle sizes.

• On-board diagnostics indicate position and fault codes for ease of troubleshooting.

• A status light signals when the unit is operating and flashes diagnostic codes if a fault occurs.

Ordering Information

Standard Equipment

| INTELLIREAM® IOL | IRM040001-IOL |

| Spray System | |

| TCP check |

Request any of the following options when ordering:

| Wire Cutter Module | IRW010099-00 |

| Nozzle Detect Assembly | IRE120099-02 |

| Nozzle Gas Flow Sensor | NAC40A |

Accessories

| Reaming Bit, 1/2" | IRB010500-00 |

| Reaming Bit, 1/2" bottleneck | IRB010501-00 |

| Reaming Bit, 15.5mm | IRB01M155-00 |

| Reaming Bit, 5/8" | IRB020625-00 |

| Reaming Bit, 3/4" | IRB010750-00 |

| IO-Link Cable, 4 pin, 10m | IRE060017-00 |

| Floor Mount Stand | IRX010001-00 |

| Anti Spatter Bulk Feed | IRS120099-06 |